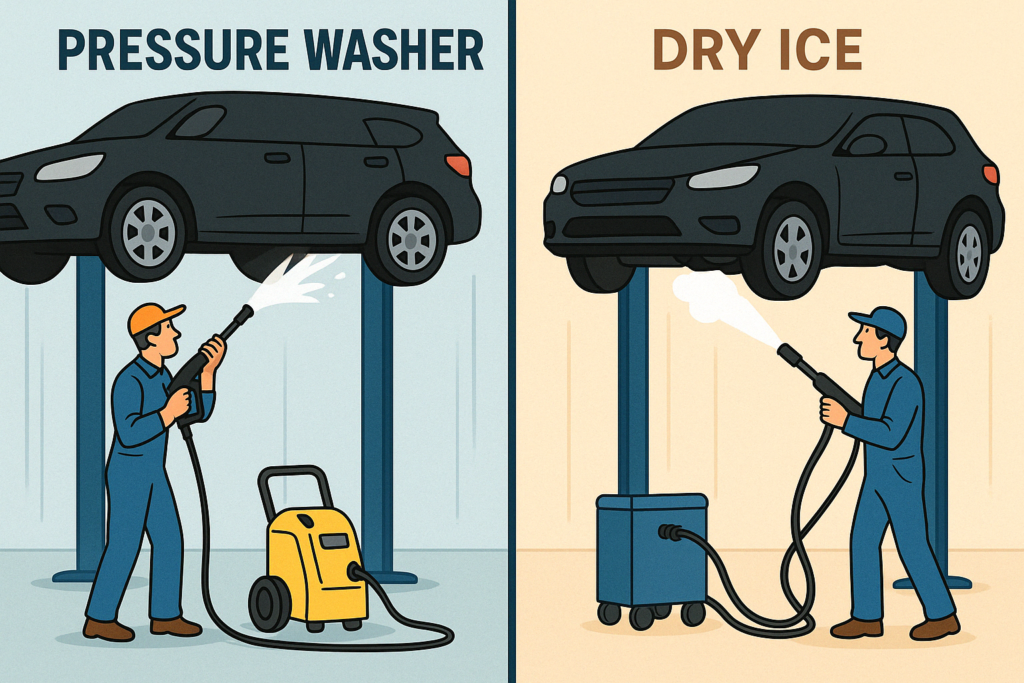

When it comes to undercarriage care, many vehicle owners debate dry ice cleaning vs pressure washing. And for good reason — pressure washing can blast away surface dirt, mud, and road grime quickly. It’s an efficient cleaning method for many vehicles.

However, not every vehicle is built the same underneath. While newer vehicles, especially off-road trucks and SUVs, are designed with more modern seals, insulation, and weatherproofing, older vehicles and collector models have much more vulnerable components.

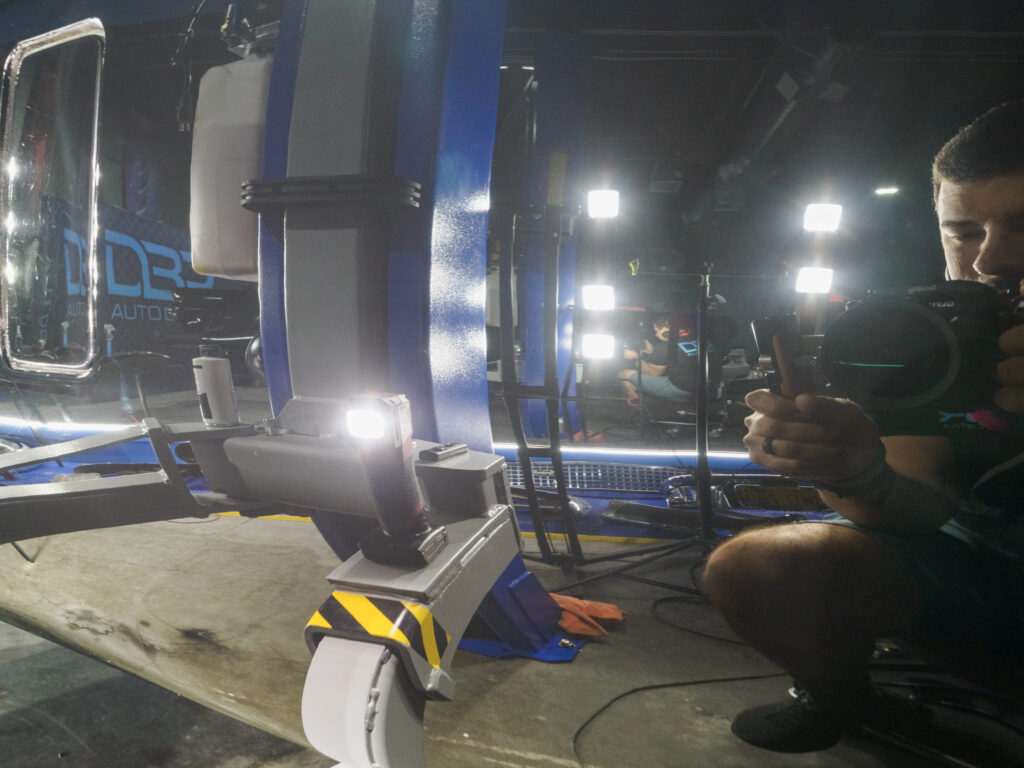

At DBR Auto Detail in Murrieta, we believe in tailoring the cleaning process to the needs of the vehicle. Depending on its age, purpose, and preservation goals, we recommend either pressure washing or dry ice cleaning.

Here’s a complete guide to how these two methods compare — and when each makes the most sense.

What Is Pressure Washing and How It Works

Pressure washing uses high pressure water spray to physically remove dirt, grime, oil, and debris from surfaces. By forcing water through a narrow nozzle at extremely high pressure (often over 2,000 PSI), it can strip away even stubborn buildup.

For vehicles, pressure washing is typically used for:

- Wheel wells

- Frames

- Suspension components

- Underside cleaning after off-roading

When paired with proper surface preparation, pressure washing can be an effective first step before applying rust inhibitors or undercarriage coatings.

When Pressure Washing Makes Sense

Pressure washing is generally safe for newer vehicles, especially modern trucks and SUVs like:

- Ford Raptors

- Jeep Wranglers

- Broncos

- Toyota Tacomas and 4Runners

These vehicles are designed with better insulation around sensitive areas like wiring harnesses, connectors, and frame seams. Traditional cleaning methods like pressure washing are fine when the goal is basic maintenance after off-roading or driving through muddy conditions.

Limitations of Pressure Washing for Vehicle Undercarriages

While pressure washing is effective for removing surface dirt and road grime, it has limitations:

- It introduces moisture into areas that might not dry quickly, like bushings, seams, and hidden cavities.

- It can force water into aging seals and gaskets over time.

- It doesn’t remove baked-on grease, oil, or carbon deposits effectively.

- It can create secondary waste — dirty water runoff that needs to be managed.

Additionally, most modern vehicles lack heavy-duty rust-proof coatings found on older vehicles. Even new trucks can start corroding after repeated exposure to water if they aren’t protected afterward. While frames are painted, cavities within the frame are usually not treated.

What Is Dry Ice Cleaning?

Dry ice cleaning — also known as dry ice blasting — is a revolutionary non-toxic and non-abrasive method for cleaning surfaces without using water, chemicals, or aggressive scrubbing.

How it works:

- Dry ice pellets (solid carbon dioxide) are accelerated using compressed air.

- Upon impact, the ice expands; the dry ice particles remove contaminants by thermal shock and sublimation (changing from solid directly into gas).

- The process lifts off dirt, oil, carbon, and grime without damaging the underlying surfaces.

Dry ice blasting technology leaves no secondary waste — only the removed contaminants that fall to the floor to be swept.

How Dry Ice Blasting Machines Work

Modern dry ice blasting machines like Cold Jet systems or Green Ice Technologies use advanced nozzles and two-hose or single-hose systems to deliver dry ice at controlled pressures.

- Pellets are stored in an insulated hopper.

- Compressed air propels the ice through a hose to the blasting nozzle.

- Operators wear insulated gloves for safety, but no harsh chemicals or hazardous materials are involved.

The result: powerful, precision surface preparation without water, sand, or harsh abrasives.

The downside is the initial investment for equipment is between $30,000–$80,000.

Advantages of Dry Ice Cleaning vs Traditional Cleaning Methods

Compared to abrasive blasting (like sandblasting or soda blasting), dry ice cleaning offers major benefits:

- No abrasion to the underlying paint, rubber, or plastic.

- No liquid residue or water intrusion.

- No dust or harmful airborne particles like in sandblasting.

- Safe for delicate surfaces, including factory coatings, cosmoline, and fragile labels that need to be preserved.

- Non-toxic and non-conductive, making it ideal for cleaning around wiring, sensors, and electrical components.

Unlike pressure washing, dry ice cleaning doesn’t just remove dirt — it carefully restores the appearance of the metal, plastics, and other materials without creating new vulnerabilities.

Check out this Porsche 911 transmission restoration we performed after 30 years of built-up grime. Learn more about how dry ice blasting works in industrial applications.

Dry Ice Cleaning for Older Vehicles and Collector Cars

For classic cars, vintage trucks, and collector vehicles, dry ice cleaning is by far the safer method.

Many older vehicles suffer from:

- Brittle seals

- Aging wiring insulation

- Delicate factory finishes

- Rare factory stickers or cosmoline coatings

Introducing moisture through pressure washing could accelerate hidden rust, corrode connectors, or even destroy valuable original details.

With dry ice cleaning, we gently remove dirt, oil, grease, and carbon deposits without damaging any underlying surfaces — preserving the originality and value of the vehicle.

Dry Ice vs Pressure Washing: Which Is Better for My Vehicle?

Here’s a quick comparison of dry ice cleaning vs pressure washing to help determine the safest and most effective option for your specific vehicle.

| Vehicle Type | Recommended Method |

|---|---|

| New off-road trucks (Ford Raptor, Jeep, Bronco) | Pressure washing (plus ceramic coating for protection) |

| Vintage vehicles (Pre-2000s) | Dry ice cleaning |

| Classic show cars | Dry ice cleaning |

| Heavily used off-roaders | Pressure washing first, then dry ice cleaning for detailing |

| Collector vehicles | Dry ice cleaning only |

At DBR Auto Detail, we always recommend the method that offers the safest, most effective cleaning for your specific vehicle — not a one-size-fits-all approach.

Why Surface Preparation Matters for Undercarriages

Whether you’re using pressure washing or dry ice blasting, proper surface preparation is critical before applying any protective coating.

- Dirt, oil, and contaminants must be fully removed.

- Dry surfaces ensure proper adhesion of undercarriage coatings or sealants.

- Skipping prep leads to premature coating failure, hidden rust, and costly repairs.

Choosing the right method—dry ice cleaning vs pressure washing—is essential to ensure proper adhesion of protective coatings and long-term rust prevention.

Dry Ice Cleaning vs Abrasive Blasting (Sandblasting, Soda Blasting)

Sandblasting and soda blasting were once popular for undercarriage and frame cleaning — but they come with major risks:

- Highly abrasive: Can remove paint, protective coatings, and even gouge metal.

- Dust control issues: Massive airborne particles requiring containment.

- Secondary waste: Requires extensive cleanup and environmental controls.

In contrast, dry ice blasting:

- Cleans without abrasion

- Leaves no secondary waste

- Is safe around sensitive surfaces

For high-end restorations and preservation-focused detailing, dry ice wins.

Environmental Benefits of Dry Ice Cleaning (Non-Toxic, No Secondary Waste)

One of the most overlooked aspects in the dry ice cleaning vs pressure washing debate is the environmental footprint each method leaves behind.

- Dry ice is made from reclaimed carbon dioxide, not new emissions.

- No hazardous substances are introduced into the environment.

- There’s no secondary runoff like with pressure washers or abrasive methods.

- No toxic chemicals or residues are left behind.

It’s the ultimate green cleaning solution — perfect for eco-conscious collectors and enthusiasts.

Why Undercarriage Coating Is Still Important After Cleaning

Even after a thorough dry ice cleaning or pressure wash, protection is key.

We strongly recommend applying an industrial-grade ceramic coating to your vehicle’s undercarriage to:

- Shield bare metal against moisture and corrosion

- Prevent buildup of new road grime and salts

- Maintain easier future cleanings

Especially in Southern California’s mix of dust, sun, and seasonal rain, undercarriage coatings make a big difference in long-term durability.

Undercarriage Care in Southern California: Murrieta, Temecula, Inland Empire

In Murrieta, Temecula, and across the Inland Empire, vehicles face unique undercarriage challenges:

- Dust buildup from dry months

- Sudden rains that trap mud and contaminants

- UV degradation weakening protective surfaces over time

Proper undercarriage cleaning and protection isn’t just cosmetic — it’s critical for the structural health of your vehicle.

Final Thoughts on Dry Ice Cleaning vs Pressure Washing for Undercarriages

If you’re deciding between dry ice cleaning vs pressure washing, consider your vehicle’s age, finish, and long-term preservation goals.

- New off-road vehicles can handle pressure washing safely but should still be coated to protect against hidden corrosion.

- Older vehicles, collector cars, and show vehicles deserve the precision, dryness, and surface-safe performance of dry ice cleaning.

At DBR Auto Detail, we focus on long-term preservation, not quick fixes.

We customize the cleaning process for every vehicle based on its needs, history, and future use.

For more information and to see more transformations, visit our Dry Ice Detailing page.

Frequently Asked Questions About Dry Ice Cleaning and Pressure Washing

What is dry ice cleaning and how does it compare to pressure washing?

Dry ice cleaning uses solid carbon dioxide (dry ice pellets) accelerated by compressed air to remove dirt, oil, and grime without water or abrasives. It’s a safe, non-conductive, non-toxic cleaning method.

Does dry ice cleaning damage paint or coatings?

No. Dry ice blasting is non-abrasive and preserves existing coatings, factory cosmoline, paintwork, and decals when properly performed.

Is pressure washing bad for old vehicles?

For older vehicles with fragile seals, aged wiring, or original finishes, pressure washing introduces moisture that can accelerate rust and corrosion. Dry ice cleaning is a safer choice.

What types of vehicles benefit most from dry ice cleaning?

- Classic cars

- Vintage trucks

- Collector vehicles

- Imported JDM cars (Skyline, Supra, etc.)

Anything where originality matters.

Is dry ice cleaning environmentally friendly?

Yes — dry ice cleaning uses reclaimed carbon dioxide, produces no secondary waste, and avoids introducing harmful chemicals or dust into the environment.

Updated 4/27/2025