At DBR Auto Detail in Murrieta, CA, we recently protected the undercarriage of a brand-new Ford Raptor with our industrial-grade ceramic coating. While many owners wait until rust or buildup becomes visible, the best time to apply an undercarriage coating is when the vehicle is brand new and clean.

Even then, prep work is absolutely critical.

Before applying any ceramic coating, we perform a detailed degreaser and acid wash of the entire underbody. Even new vehicles can have shipping film, factory oils, or early signs of dirt and road residue that will prevent proper coating adhesion. Our multi-step chemical prep ensures the surface is completely clean, decontaminated, and ready for long-term protection.

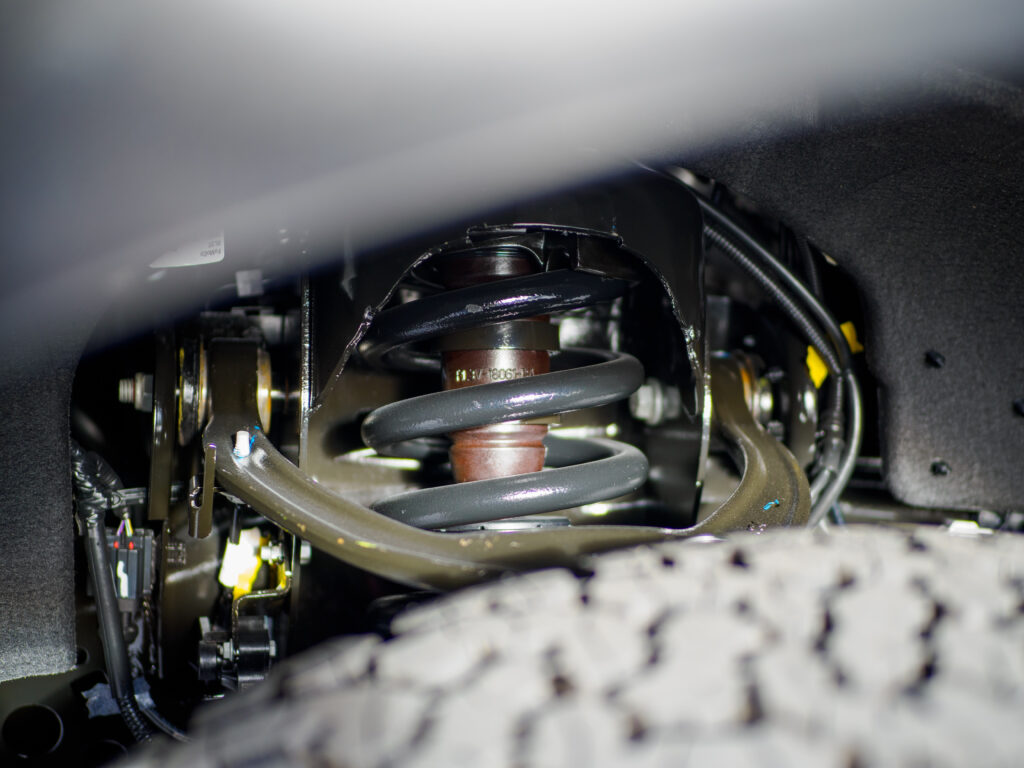

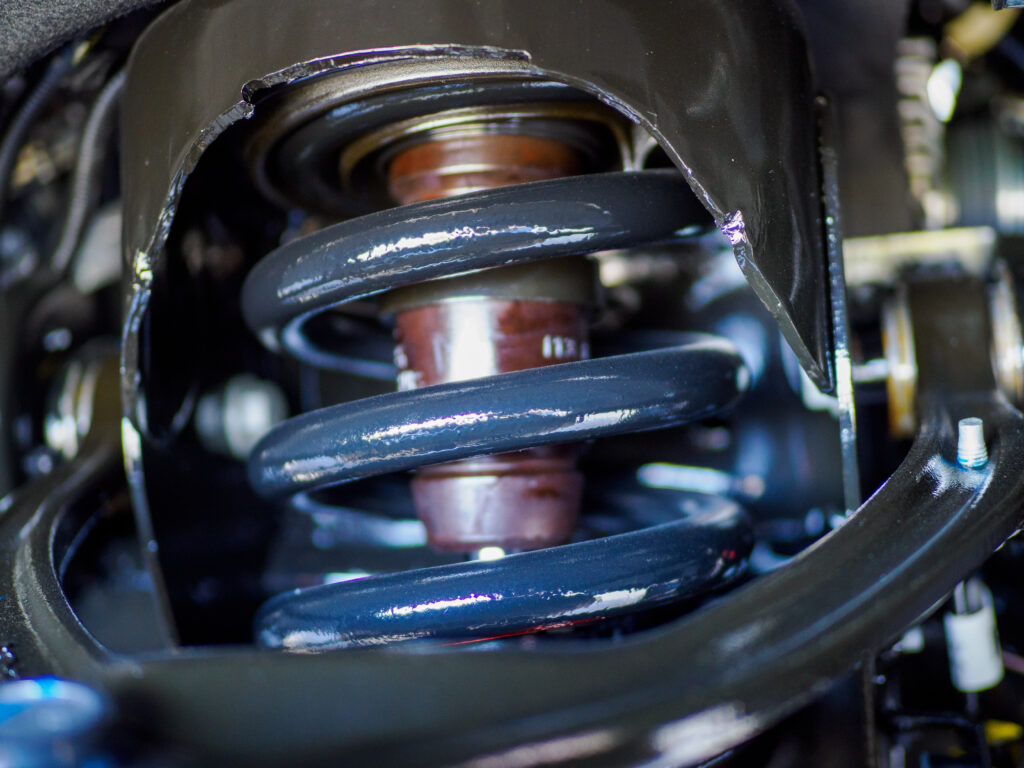

After prep, we apply our industrial ceramic coating across the frame, suspension, and undercarriage. This high-temp formula creates a durable shield against water, grime, corrosion, and salt—ideal for trucks like the Raptor that are built to be used.

Table of Contents

ToggleWhy New Is Best

Starting the coating process when the vehicle is brand new helps the coating last longer and perform better. You’re not just cleaning up after damage—you’re preserving factory condition from the beginning and extending the life of key components.

Protect Your Investment

If you want to protect your new truck from the underside up, now is the time.

Contact DBR Auto Detail in Murrieta, CA to schedule your professional undercarriage ceramic coating service.